Unveiling the Density of 190 Proof Ethanol: Embark on a journey into the realm of chemistry, where we delve into the intricate properties, production methods, and myriad applications of this versatile substance. Join us as we unravel the secrets of 190 proof ethanol, exploring its molecular structure, physical characteristics, and industrial significance.

From its humble beginnings in fermentation to its widespread use as a solvent, fuel, and pharmaceutical ingredient, 190 proof ethanol plays a crucial role in various industries. Discover the factors influencing its production yield and purity, as well as the safety guidelines and regulations governing its handling and storage.

Properties of 190 Proof Ethanol

190 proof ethanol, also known as pure grain alcohol, is a highly concentrated form of ethyl alcohol with a specific composition and unique properties.

If you’re studying for your GA permit test, you might want to check out this handy cheat sheet . It’s got all the info you need to know about traffic laws, road signs, and safe driving practices. Back to the science corner, the density of 190 proof ethanol is 0.814 g/mL at 20 °C, making it less dense than water.

Chemically, 190 proof ethanol is composed of two carbon atoms, six hydrogen atoms, and one oxygen atom, with a molecular structure of CH 3CH 2OH. This structure gives it a hydroxyl group (-OH) attached to a two-carbon aliphatic chain.

Physical Properties

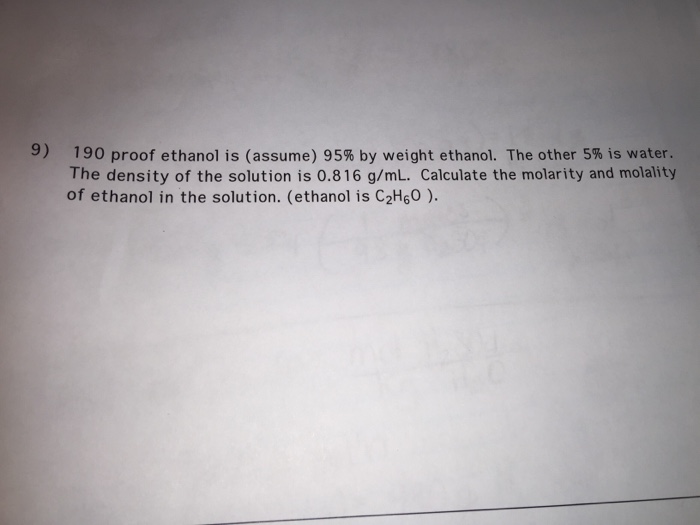

190 proof ethanol exhibits distinct physical properties due to its molecular structure. It has a density of 0.816 g/mL at 20°C, which is lower than water due to the presence of the hydroxyl group. The boiling point of 190 proof ethanol is 78.3°C,

and its freezing point is -114.1°C.

Solubility and Compatibility

190 proof ethanol is highly soluble in water and other polar solvents. It is also compatible with many organic compounds, including oils, fats, and hydrocarbons. This property makes it a versatile solvent for various applications.

Production Methods

190 proof ethanol can be produced through various methods, each with its own advantages and considerations. These methods include fermentation, distillation, and dehydration.

Fermentation

Fermentation is a biological process that involves the conversion of sugars into ethanol by yeast or bacteria. In the production of 190 proof ethanol, a high-sugar feedstock, such as molasses or corn syrup, is fermented using a specific strain of yeast that can tolerate high alcohol concentrations.

Distillation

Distillation is a physical process that separates liquids based on their boiling points. In the production of 190 proof ethanol, the fermented liquid is heated to vaporize the ethanol, which is then condensed and collected. This process can be repeated multiple times to achieve a higher purity of ethanol.

Dehydration, Density of 190 proof ethanol

Dehydration is a chemical process that removes water from a substance. In the production of 190 proof ethanol, water is removed from the ethanol using a drying agent, such as molecular sieves or calcium oxide. This process is typically used to achieve a higher concentration of ethanol than is possible through fermentation and distillation alone.

Applications

proof ethanol finds wide application in various industries and commercial sectors. Its versatility stems from its unique properties, including its high purity, solvent power, and reactivity.

As a solvent, 190 proof ethanol is employed in the manufacturing of paints, coatings, adhesives, and cleaning products. It is also used in the extraction of essential oils, fragrances, and flavors from natural sources. Additionally, it serves as a carrier solvent in the pharmaceutical industry for the preparation of tinctures, extracts, and other liquid formulations.

Fuel

proof ethanol is a renewable and sustainable fuel source. It can be blended with gasoline to create ethanol-gasoline blends, which are commonly used in vehicles. Ethanol-gasoline blends reduce greenhouse gas emissions and contribute to cleaner air quality.

Chemical Intermediate

proof ethanol is a valuable chemical intermediate used in the production of a wide range of chemicals, including acetic acid, ethyl acetate, and diethyl ether. These chemicals are further utilized in the manufacturing of plastics, textiles, and pharmaceuticals.

Beverages, Pharmaceuticals, and Personal Care Products

proof ethanol is the primary alcohol used in the production of alcoholic beverages, such as vodka, whiskey, and gin. In the pharmaceutical industry, it is used as a solvent and preservative in the preparation of medicines and vaccines. Furthermore, it is a common ingredient in personal care products, including perfumes, cosmetics, and toiletries.

Safety and Handling

190 proof ethanol is a highly flammable and toxic substance that requires careful handling and storage to ensure safety. Understanding its potential hazards and following proper safety guidelines is crucial.

Flammability:190 proof ethanol has a low flash point, meaning it can easily ignite even at room temperature. Keep it away from open flames, sparks, or any heat sources.

Toxicity:Ethanol is toxic if ingested, inhaled, or absorbed through the skin. Exposure can cause irritation, dizziness, nausea, and even coma in severe cases. Ensure proper ventilation when working with ethanol, and avoid direct contact.

Health Hazards:Prolonged or excessive exposure to ethanol can lead to health issues such as liver damage, heart problems, and cancer. Handle it responsibly and minimize exposure.

Proper Storage

- Store 190 proof ethanol in a cool, well-ventilated area away from direct sunlight.

- Keep it in tightly sealed, corrosion-resistant containers with proper labeling.

- Ground and bond all equipment used for handling ethanol to prevent static discharge.

Waste Disposal

- Dispose of waste ethanol through a licensed hazardous waste disposal company.

- Never pour ethanol down the drain or into the environment.

- Small amounts of ethanol can be evaporated in a well-ventilated area.

Regulations and Standards

The production, distribution, and use of 190 proof ethanol are strictly regulated to ensure public safety and prevent misuse. These regulations vary depending on the jurisdiction, but generally adhere to a comprehensive framework established by government agencies.

Government Agencies

Government agencies, such as the Food and Drug Administration (FDA) in the United States and the European Chemicals Agency (ECHA) in the European Union, are responsible for enforcing regulations related to ethanol production and use. These agencies establish guidelines for the manufacturing process, packaging, labeling, and transportation of ethanol to minimize risks to human health and the environment.

Industry Standards and Best Practices

In addition to government regulations, the ethanol industry has developed its own standards and best practices for handling ethanol safely and responsibly. These standards cover various aspects, including:

- Proper storage and handling techniques to prevent spills and leaks.

- Training and certification programs for individuals handling ethanol.

- Emergency response plans in case of accidents or incidents.

By adhering to these regulations and standards, manufacturers, distributors, and users of 190 proof ethanol can minimize the risks associated with its use and ensure the safety of the public and the environment.

Market Analysis: Density Of 190 Proof Ethanol

The global market for 190 proof ethanol is vast and dynamic, driven by its diverse applications in various industries. Major producers include the United States, Brazil, and China, while key consumers are spread across North America, Europe, and Asia.

Major Trends

The industry has witnessed significant growth in recent years, fueled by rising demand for ethanol as a biofuel and solvent. The increasing focus on sustainability and the need for renewable energy sources have further propelled market expansion. Additionally, the growing popularity of alcoholic beverages has contributed to the demand for high-proof ethanol for use in production.

Factors Influencing Supply and Demand

Several factors influence the supply and demand of 190 proof ethanol. These include:

- Availability and price of feedstocks, such as corn and sugarcane

- Government policies and regulations

- Technological advancements in production processes

- Economic conditions and consumer demand

Price Fluctuations

The price of 190 proof ethanol fluctuates based on supply and demand dynamics, as well as global economic conditions. Market volatility can be influenced by factors such as crop yields, geopolitical events, and changes in government regulations.

Environmental Impact

The production and use of 190 proof ethanol have environmental implications that require careful consideration. Its impact on greenhouse gas emissions and climate change, as well as the potential for sustainable production and disposal practices, are important factors to evaluate.

Greenhouse Gas Emissions

Ethanol production, whether from corn or other feedstocks, can contribute to greenhouse gas emissions through various stages of the process. Cultivation of crops requires land use, which can lead to deforestation and the release of carbon dioxide. Additionally, the fermentation and distillation processes involved in ethanol production generate emissions of carbon dioxide and other greenhouse gases.

Climate Change

The release of greenhouse gases, including carbon dioxide, methane, and nitrous oxide, contributes to climate change. These gases trap heat in the atmosphere, leading to rising global temperatures, changes in precipitation patterns, and more extreme weather events. Ethanol production can contribute to these emissions, and its role in climate change must be carefully assessed.

Sustainable Production

Sustainable production practices for 190 proof ethanol aim to minimize its environmental impact. These practices include using renewable energy sources in the production process, implementing energy-efficient technologies, and reducing waste and emissions. Additionally, sustainable feedstock sources, such as non-food crops or agricultural residues, can help mitigate the environmental impact of ethanol production.

Disposal

Proper disposal of ethanol is crucial to prevent environmental contamination. Ethanol can be recycled and reused in certain applications, but it can also be safely disposed of through incineration or biodegradation. Proper disposal methods help prevent ethanol from entering the environment and causing potential harm to ecosystems.

General Inquiries

What is the density of 190 proof ethanol?

190 proof ethanol has a density of 0.816 grams per milliliter at 20 degrees Celsius.

How is 190 proof ethanol produced?

190 proof ethanol is typically produced through a combination of fermentation, distillation, and dehydration processes.

What are the primary applications of 190 proof ethanol?

190 proof ethanol is widely used as a solvent, fuel, and chemical intermediate in various industries, including pharmaceuticals, cosmetics, and beverages.